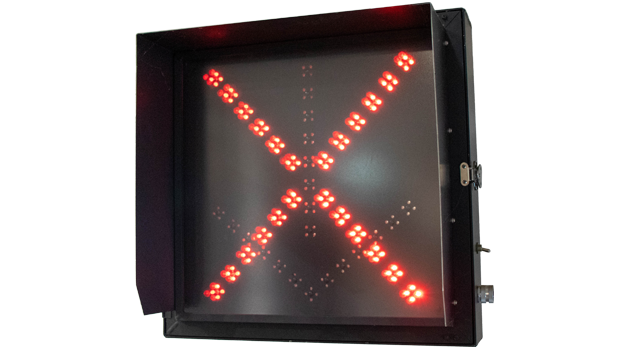

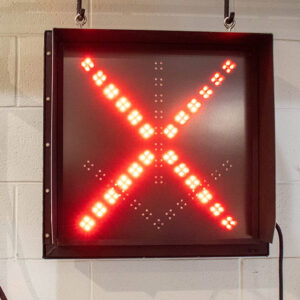

Customizable Lane Control Signs

National Sign and Signal’s super energy-efficient LED dynamic lane control signs set the standard for ultra-bright, fail-safe traffic control applications, while consuming less than half the energy of traditional traffic products. National’s DMS signs cost significantly less to operate but have exceptional message visibility and clarity and can display customized messages in all standard ITE colors. National’s signs are NTCIP compliant and can be customized to meet specific requirements.

Notable Features:

- Low power consumption – 12 VDC, 110-230 VAC or solar power options

- Single or double face models

- Industry leading ventilation technology protects internal components

- 2mm aluminum housing, fully welded with internal support members

- 60,000 hr. LED life expectancy with minimal to no light degradation

- Greater than 10:1 contrast ratio over full ambient light level range

- GE LED caps provide EN12966 B6 & L3 compliance